The year 2025 marks an era of unprecedented transformation, driven by the relentless evolution of artificial intelligence (AI). Every day, AI adapts, learns, and reshapes industries, pushing the boundaries of what was once thought possible. As we stand at this crossroads, one sector experiencing a massive shift is renewable energy. Yes, you read that right; wind and solar energy companies are embracing this new dawn of evolution, leveraging AI to tackle challenges that were unimaginable a decade ago.

For wind energy operators, data is the lifeline of their operations. Wind farms monitor and analyze a myriad of metrics daily, including turbine vibrations, gearbox temperatures, rotational speeds, wind speeds, wake effects between turbines, and even dirt accumulation on turbine blades. If left undetected, these issues can escalate, reducing energy output and increasing wear and tear on critical components- ultimately leading to higher maintenance costs and operational disruptions. Even minor inefficiencies, such as fluctuations in blade rotation or subtle changes in gearbox performance, can go undetected for days or even weeks. By the time these issues are identified, the damage may already be done, resulting in costly repairs and significant downtime that could have been avoided with timely intervention.

AI-driven predictive maintenance leverages vast amounts of data collected from sensors embedded in wind turbines. These sensors monitor various parameters, such as vibration, temperature, and rotational speed, providing real-time data on the health of the turbines. AI algorithms analyze this data to detect patterns and anomalies that may indicate potential failures.

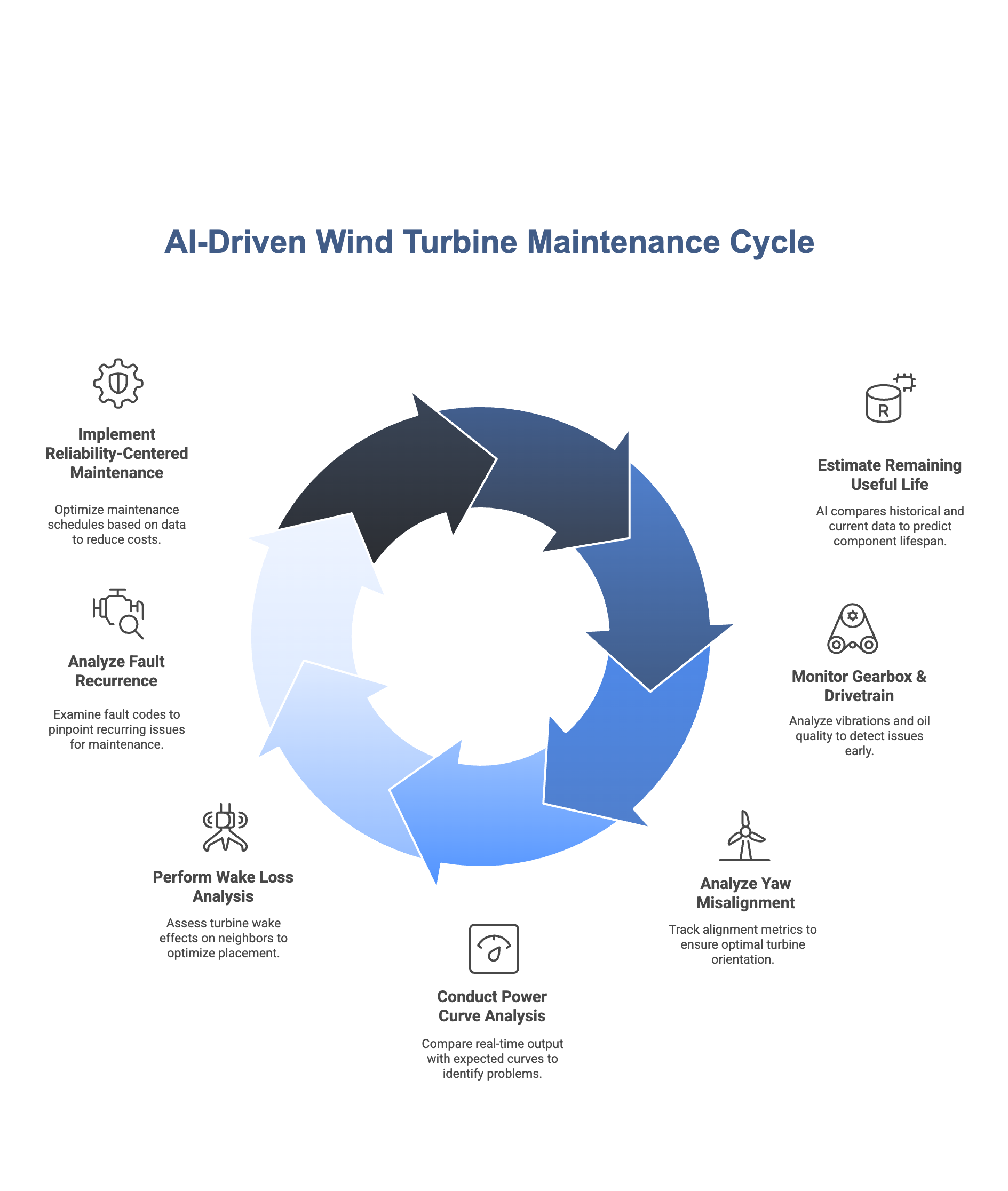

Yet, predictive maintenance goes far beyond just spotting anomalies. Advanced AI analytics now include:

The renewable energy market is becoming increasingly competitive. With AI-driven predictive maintenance:

As industry leaders continue to prove the efficacy of predictive maintenance, it’s clear that adopting this approach is not just an option, it’s a necessity for sustainable growth in wind energy operations.

Imagine if someone had told you ten years ago that manual labour hours spent on monitoring these systems could be eliminated. Or that you wouldn’t have to constantly react to equipment failures because a technology could predict them before they happen. It would have seemed far-fetched back then- a pipe dream. But today, this is reality. AI-driven predictive maintenance has emerged as the game-changer for wind energy operators.

This technology doesn’t just automate menial tasks; it redefines efficiency. By analyzing real-time data from embedded sensors and historical trends, AI can anticipate equipment failures with remarkable accuracy. It allows operators to schedule maintenance proactively rather than reactively, reducing downtime by up to 35% and cutting maintenance costs by as much as 25%.

At GreenBridge, we understand that the future of wind energy lies in innovation and efficiency. Our advanced AI-data agents and AI solutions are designed to empower operators with actionable insights, enabling them to prevent costly failures and optimize turbine performance. By leveraging AI-driven analytics, GreenBridge equips wind energy companies to stay ahead of potential issues, ensuring uninterrupted energy production and reduced operational costs.

As a trusted partner in renewable energy industry, GreenBridge is committed to driving sustainable growth while delivering tangible results. With our expertise and cutting-edge technology, we help operators not only adapt to the challenges of today but also thrive in the opportunities of tomorrow. The time to act is now! Let GreenBridge guide your transition to smarter, more efficient wind energy operations. Together, we can build a greener, smarter future.

Kimpreet Kour Balhar

Author

Deepu Dany Lal

Expert Insights

Stay informed with our latest updates, industry innovations, and actionable insights tailored to drive your sustainability and operational excellence.